Nuvonis has developed a new high-yield platform process for the production and purification of Newcastle disease virus (NDV). The process is based on a novel avian cell line CCX.E10, an alternative to traditional egg-based production and monolith chromatography for purification. This allows for robust manufacturing and enables new NDV product development.

What is Newcastle Disease?

Newcastle disease is an extremely infectious condition among domesticated poultry and other avian species. It has high morbidity and mortality rates among infected birds. This gives the disease significant economic importance. Vaccines are used globally to protect against Newcastle disease infection.

Traditional Vaccines Using Egg-based Production and CEFs (Chicken Embryo Fibroblasts)

Many NDV-based vaccines and viral vectors are still produced in traditional substrates such as embryonated chicken eggs or primary chicken embryo fibroblasts (CEFs).

Embryonated chicken eggs and CEFs are not a robust manufacturing system for the following reasons:

- They require large numbers of specific–pathogen–free (SPF) embryonated eggs to generate primary cell cultures.

- They are susceptible to microbial contamination.

- Heterogeneity in their starting material leads to variability in NDV yield and quality.

Avian cell lines have become a promising alternative to egg-based productions and can replace egg and chicken embryo fibroblast technologies for human and veterinary vaccine manufacturing.

Nuvonis Novel Avian Suspension Cell Line as Alternative to Egg-based Production

Nuvonis recently introduced the quail-derived cell line CCX.E10. This cell line offers the following advantages over other current avian cell lines:

- It was developed without the use of foreign genes and viral sequences and is thus not a genetically modified organism (GMO) cell substrate.

- The cell line grows in suspension culture, but an anchorage-dependent version is available for companies that want to use existing production infrastructure (e.g. roller bottles, stacked-tray systems, and microcarriers).

- The CCX.E10 line also grows in commercially available serum-free and animal-component–free media.

- The CCX.E10 cell line is available as a GMP cell line and was tested according to ICH guidelines.

The CCX.E10 cell line has potential as alternative to egg-based production and as a platform technology for a broad range of NDV products in human and veterinary medicine.

Excellent Results in Recovery and Purity and a Proven Alternative to Egg-based Production

Among others, the results showed:

- Virus purification lasts less than an hour.

- 75% recovery of infectious particles.

- 0% depletion of proteins.

- 9% removal of DNA impurities.

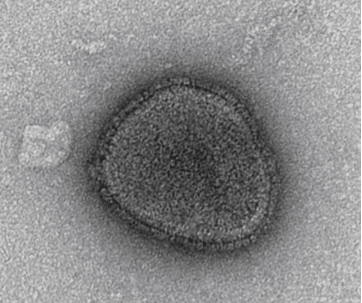

- Transmission electron microscopy (TEM) confirmed the presence of intact NDV particles in the eluate.

Enabling Vaccine Manufacturing

The described production and purification processes represent a robust manufacturing tool and present an efficient alternative to traditional egg-based production. The methodology supports the optimization of NDV processes and enables biopharmaceutical companies to develop new NDV products.

Besides current applications in veterinary vaccines, NDV also has considerable potential as a vector for treatment of infectious diseases and cancers in humans.